parallax bg

OUR SOLUTIONS Self-funding processes that engage your greatest asset – your people

1. Integrated Performance Solution

Infuse new energy, capacity and capability with Integrated Performance Solution

Integrated Performance Solution engages and empowers a manufacturing plant’s greatest asset – its people. It is the self-funding process that begins with a robust assessment that identifies and priorities measurable business and technical systems improvement opportunities. Integrated Performance Solution results in the formation of work teams that are trained to carry out certain supervisory responsibilities that are more effectively and efficiently executed at the operative level. This opens up time and capacity for supervisors and management to focus on higher value initiatives. Integrated Performance Solution unlocks the spirit of ownership and entrepreneurial drive at each level of the organization by infusing new organizational energy, capacity and capability, and results in measurable positive effects to plant performance and profitability.

2. Daily Results Management

A satisfied client of Phoenix Solutions was able to garner a 21% improvement in OEE within 6 months.

The magic behind Daily Results Management is the data-driven, short interval controls that achieve results! Discipline and rigor are created by a system of results-focused accountability meetings that entrust teams to find resolutions quickly and efficiently. Daily Results Management identifies performance gaps, assigns ownership, and results in an integrated system of performance improvement. Challenges and successes are continually measured, tracked and reported. As management discovers the positive results of Daily Results Management, they adopt the model for all levels of the organization.

3. Project Performance

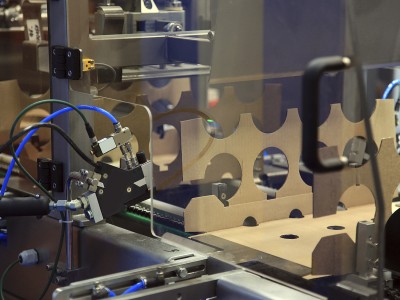

A food packaging plant launched a critical project on time at 100% full production and meeting all KPI’s within the first 4 days with the help of Phoenix Solutions

Project Performance is a self-funding process that engages engineering and operations in the planning of vertical launch projects to identify performance gaps and challenges, and create strategic alignment early on. Project Performance gets the receiving organization involved in identifying hurdles that might not have been part of the initial plan. The result is operational readiness, which eliminates the days or months of performance gaps that can cost companies time and money. This seamless adoption ensures teams are engaged and projects can be successfully executed within scope, on time and under budget!

As a technology supplier we were amazed how well Phoenix prepared the client to take advantage of their investment. Because we worked hard to get the equipment right and the Phoenix process kept the operational team engaged in the project, it started up incredibly well and has continued to perform well since then.

Jim Lyons, Strategic Account Manager, Kliklok Woodman

4. Proactive Maintenance

A valued private label manufacturing client achieved a 16% increase in OEE and and a 72% decrease in unscheduled “reactive” maintenance time

Proactive Maintenance enhances production performance and profitability by transforming maintenance from a tactical and reactionary part of the organization into a strategic, proactive component. Proactive Maintenance increases overall equipment effectiveness (OEE) by 10-20% and decreases maintenance costs resulting in increased profitability of the plant. Proactive Maintenance ends the torturous “blame game” that creates friction between the maintenance department and operations departments. By engaging representatives from both groups in this process, transparency increases dramatically while the plant makes the meaningful transition from a reactive to a proactive maintenance strategy.

5. Find a Million

A granola bar plant achieved annualized savings of $840K in less than 4 months and a bottling plant recognized a savings of $1.9MM recognized after 2 years with Phoenix Solutions

Find A Million is the answer to boosting the P&L in 4-6 months by a $million or more. The return on the initial investment in Find A Million with Phoenix is typically a ten fold, boost to the bottom line achieved by uncovering tactical performance improvements that are quick, practical and sustainable.